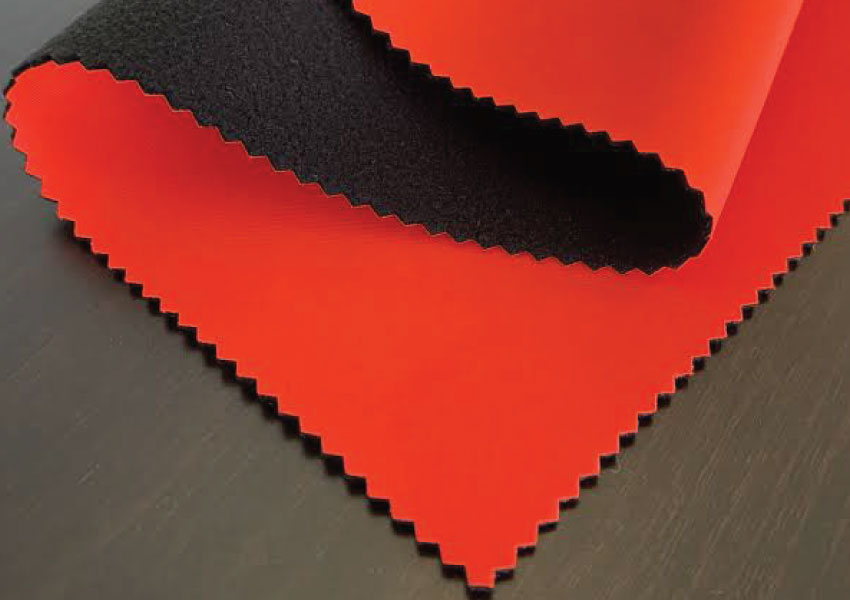

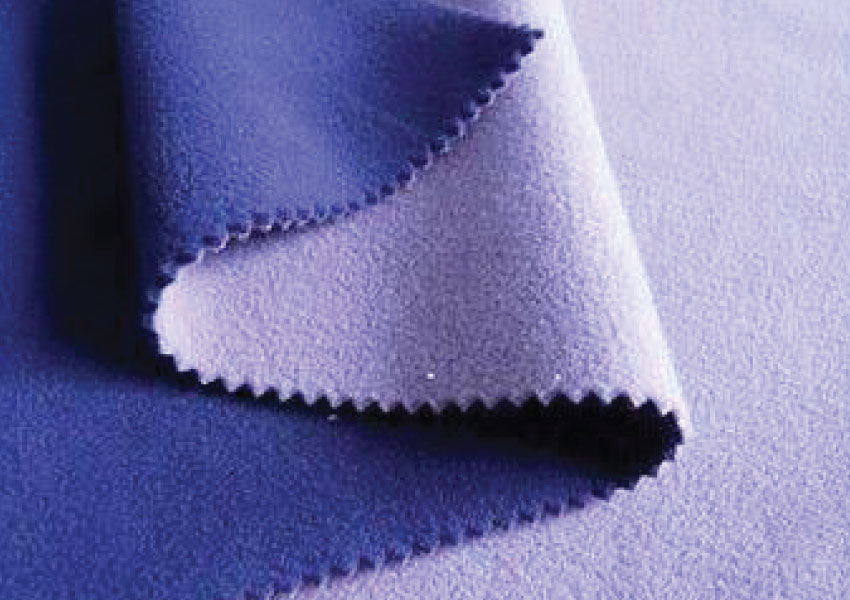

Advanced laminated fabrics in textile technology refer to fabrics that are composed of multiple layers of materials, such as fabric, foam, and film, that are laminated together to create a single, high-performance material. These fabrics are designed to have superior properties such as waterproofing, breathability, and durability.

Advanced laminated fabrics: superior performance, maximum protection

One of the key advantages of advanced laminated fabrics is their versatility. They can be used in a wide range of applications, from outdoor gear to medical textiles to automotive interiors. In the outdoor industry, laminated fabrics are used to make high-performance rainwear, tents, and backpacks. The laminated layers create a waterproof barrier while allowing air to circulate, keeping the wearer dry and comfortable.

The future of textiles: advanced laminated fabrics

Advanced laminated fabrics are also used in medical textiles, where they are used to create sterile and protective barriers for medical equipment and supplies. These fabrics are designed to be lightweight, flexible, and durable, making them ideal for use in medical environments.

In the automotive industry, advanced laminated fabrics are used to create durable and stylish interiors. The laminated layers create a barrier that is resistant to water, stains, and UV radiation, making them ideal for use in car seats, door panels, and headliners. Overall, advanced laminated fabrics provide a versatile and high-performance option for a wide range of end uses. Their ability to combine multiple materials into a single material with superior properties makes them a popular choice in several industries.